A program for educational institutions that applies business management skills to promote saving and reducing waste.

The Optimizing with Energy program is a program for educational institutions that applies the best practices of business management to generate savings, reduce waste and time, mobilize people and promote behavioral changes.

The applied practices are based on Lean, a methodology that integrates methods and tools developed since the 50s/60s in the industrial sector and, in particular, in the automotive industry, by Toyota.

Currently, the benefits obtained by applying the Lean methodology to companies in all sectors are being realized. The correct application of LEAN tools allows you to save energy, time, space and manage budgets effectively and optimally. These tools are based on several key principles, including transparency, visual management, the involvement of all employees and simplification. The goal is to minimize waste, improve processes and add value.

How does the program work?

The project involves following a program of 5 workshops over 9 to 10 months. After this, most schools put into practice everything that they have learned from Lean and apply it gradually where necessary, they are always supported by a team of EDP employees with Lean skills.

The school will set its strategic priorities and progressively create the team that will initiate and implement the continuous improvement actions that everyone has identified together. This involves students, assistants, teachers and the school board.

Together and based on the LEAN methodology, the main causes and improvement actions are identified with a cost-benefit analysis, and these are then prioritized and consequently implemented.

The implemented actions are followed up and monitored by the team, in order to assess their effectiveness and their beneficial impact.

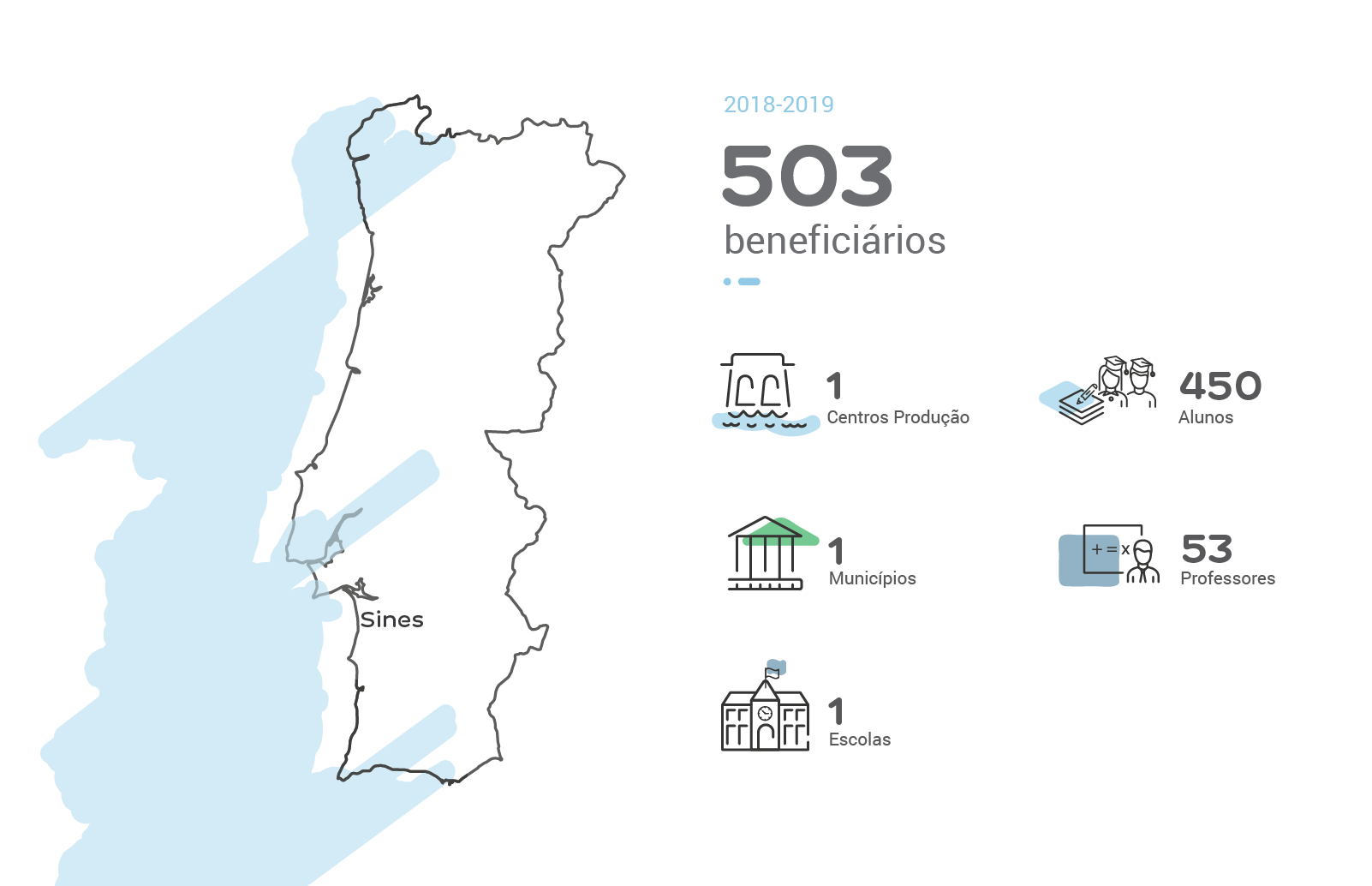

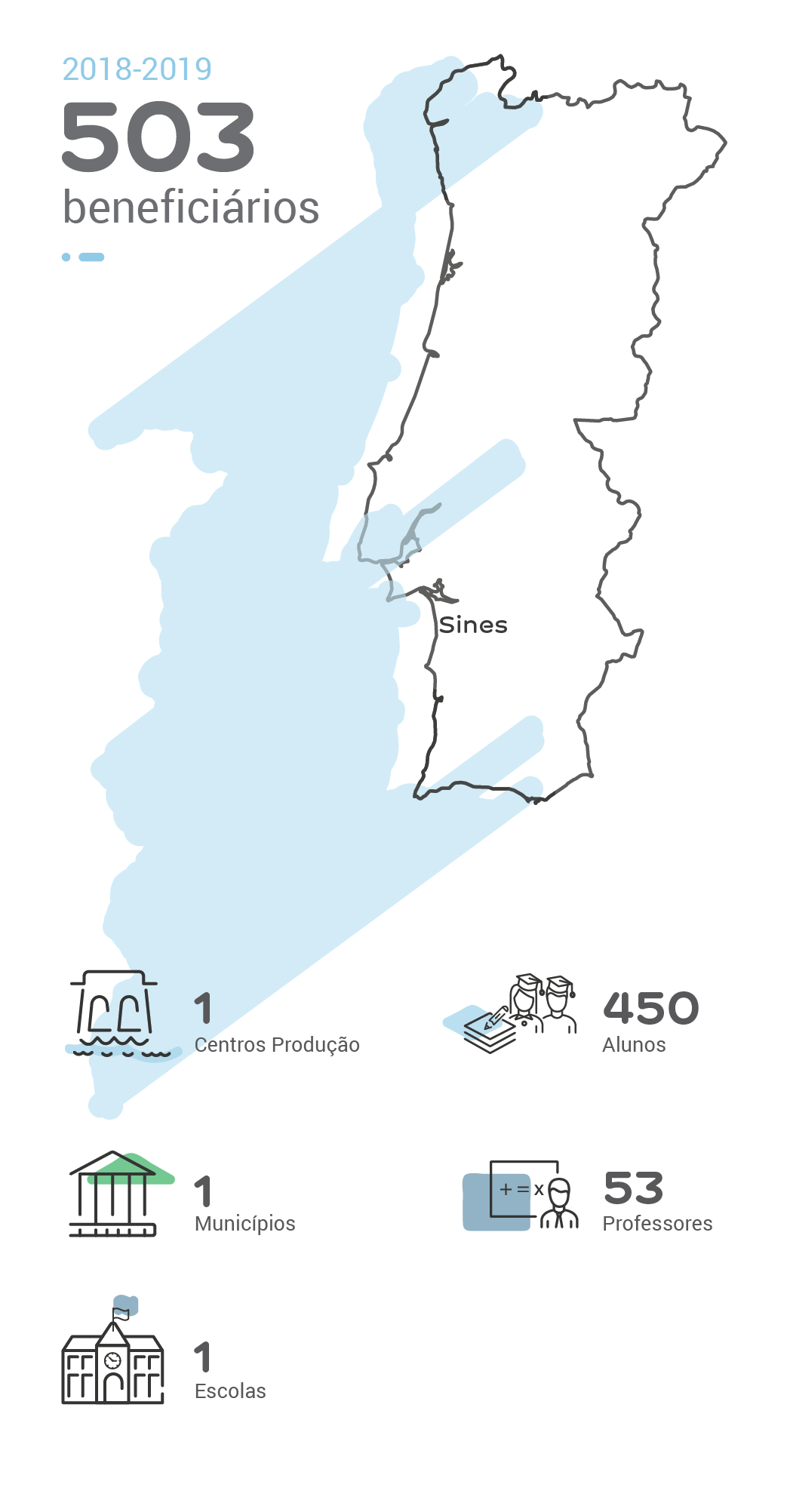

Optimizing with Energy in 2018/2019

Check out the regions covered by this school year's program.